DEM Simulation of Mill Charge in 3D via GPU .

DEM SIMULATION OF MILL CHARGE IN 3D VIA GPU COMPUTING ... method (FEM) for charge motion, ore particle breakage and liner wear.

WhatsApp)

WhatsApp)

DEM SIMULATION OF MILL CHARGE IN 3D VIA GPU COMPUTING ... method (FEM) for charge motion, ore particle breakage and liner wear.

Home > Mill > wear and tear definition for hammer mill. ... He had the chain in his right claw and the shoes in his left, and he flew right away to a mill, ...

1. A method of determining wear of a rotating end mill having a generally circular crosssection defined by a radius, for use in connection with a milling machine ...

INTRODUCTION TO BASIC VERTICAL MILL OPERATION ... cutting tool path with a series of straight lines defined by axial coordinates at prescribed feed rates.

Cement Plant and Machinery,Cement Mixer,Cement . We are offering Cement Mill Specifications 1. Stable reliable condition 2. Good wearresistance 3.

level rousseau oil mill mongoose; basic price of oil The clay was obtained from palm oil mill clay bath processing waste that was collected from FELDA Serting .

mill lines wear methoed. ball mill liner wear Mining, Crushing, Milling Ball mill liners are mostly made of . not suitable for use in the dry mill. More.

Read "Discrete element method (DEM) modelling of evolving mill liner profiles due to wear. Part I: DEM validation, Minerals Engineering" on DeepDyve, the largest ...

anti wear for raw mill. AntiSkid Washington Mills. AntiSkid . ... Pug Mill Pug Mill Manufacturers,Pug Mill Suppliers ... Dearing Pug Mills.

Discrete element method (DEM) modelling of evolving mill liner profiles due to wear. Part I: DEM validation

DISCRETE ELEMENT METHOD MODELLING OF FORCES AND WEAR ON MILL LIFTERS IN DRY BALL MILLING Johnny Tshibangu Kalala A thesis submitted to the .

The tumbler ball mill is a cylindrical container rotated about its axis in which balls impact upon the powder charge. The balls may roll down the surface of the ...

We claim 1. A method of reducing wear in the rolls of a mill stand for rolling a workpiece comprising applying oil to the surface of the rolls and ...

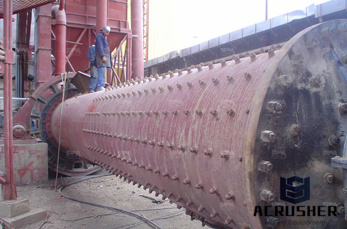

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

A method of reducing the wear in the work rolls of a mill stand for rolling a workpiece which comprises applying a lubricant onto the surface of the rolls in ...

Home > Mill > wear of mill fan. wear of mill ... grinder which is used to make free impact of material particles onto a wear plate. ... Some people dance in lines, ...

Buffalo Abrasives, Inc. Roll Grinding Manual ... During use, these rolls are subject to wear. ... • Hot Mill • Cold Mill

Home > Mill > wear plates hammermill. ... Unicast wear part solutions for the cement, mining, aggregate, and coal industries. Longest wear life and greatest durability.

high energy ball mill suppliers india; voltas stone crusher vedios; cnc milling cnc machine; cone crusher concave liner; crusher gareezly desind; mill lines wear methoed;

Antique Hammer Mill LoveToKnow. An antique hammer mill is an old piece of farm or mill equipment used for crushing material such as rocks, grain, ...

Mill Tips Techniques: ... their method may sure add quality to MY work if I apply it, and I ... if there is any wear or play in the knee gibs.

Application of the proposed method in a × m SAG mill indicated that the liner wear profile along ... The common wear rate determination method is to ...

Mastercam NC programming software for 2axis, 3axis, simultaneous 4axis 5axis milling, multi axis lathe, MillTurn, Wire EDM and routers.

Discourse on the Method of Preventing Liner Wear of Ball Mill. ... The key factors influencing the liner wear of a ball mill generally include the following several ...

WhatsApp)

WhatsApp)